Steel Angel Tube Tower Galvanizing Equipment

Steel Angel Tube Tower Galvanizing Equipment

Steel Angel Tube Tower Galvanizing Equipment

1.1 Classification of batch hot-dip galvanizing process

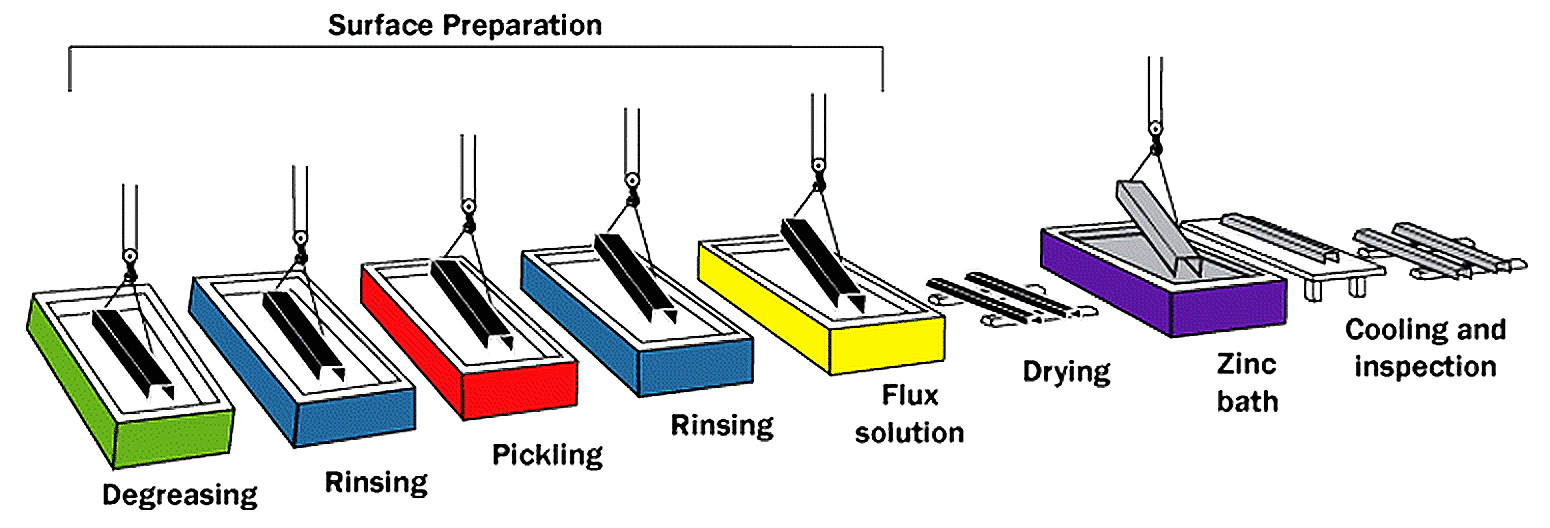

The "batch hot-dip galvanizing" process consists of three process steps: "pre-plating treatment", "hot-dip galvanizing (hot-dip galvanizing, galvanizing)" and "post-plating treatment"."Pre-plating treatment" includes: degreasing (removing old paint), pickling and rust removal, dipping in flux and drying."Post-plating treatment" includes: cooling, passivation and workpiece trimming, etc. Some products may also need to be painted."Hot-dip galvanizing" includes: zinc bath ashing, workpiece zinc dipping, zinc bath cleaning, zinc slag extraction, loose zinc recovery, etc.According to different galvanizing methods, the batch hot-dip galvanizing process is usually divided into "wet" hot-dip galvanizing and "dry" hot-dip galvanizing.

"Wet" hot-dip galvanizing"Wet" hot-dip galvanizing is to directly cover the surface of the zinc bath with the fluxing solvent, and the flux layer is thickly covered on the entire surface of the zinc bath, or only on the surface of the zinc bath on one side of the zinc pot partition. After degreasing and pickling, the workpiece can enter and exit the zinc solution through the plating flux layer, or directly immerse in the zinc solution, and pass through the solvent coating under the partition to take out; or pass through the solvent layer during immersion, and pass through the partition The bottom is taken out directly from the zinc liquid.

2. "Dry" hot-dip galvanizing"Dry" hot-dip galvanizing is to place the aqueous solution of the fluxing solvent (referred to as the fluxing solution) in a separate fluxing bath, and dip the degreased and pickled workpiece into the fluxing bath (referred to as "assisted plating") Finally, it is dried and then immersed in zinc solution to obtain a hot-dip galvanized layer.

3. Comparison of "wet" and "dry" hot-dip galvanizing processesThe merits of the two processes of "wet" hot-dip galvanizing and "dry" hot-dip galvanizing are still a subject of debate in the batch hot-dip galvanizing industry. In fact, which process to choose should be determined according to the type and demand of the workpiece. (1) Generally speaking, the "wet" hot-dip galvanizing process is mostly used to obtain a thinner galvanized layer, because when the workpiece is pulled out from the flux layer on the surface of the zinc liquid, due to the impact of the flux layer on the surface of the workpiece It has the function of wiping, which is conducive to the rapid return of the zinc liquid on the surface of the workpiece, so that the galvanized layer on the surface of the workpiece is thinner.For complex workpieces, since the workpiece is not easy to dry, the flux layer can prevent zinc "splash" (commonly known as "zinc explosion"). In addition, when the "wet" hot-dip galvanizing process is used, the number of times the workpiece is lifted can be reduced, and the zinc dust produced is also relatively small.However, if the plating flux remains on the surface of the workpiece after rinsing, the flux will contaminate and corrode the workpiece. It is easy to cause zinc loss when replacing the plating flux layer, and at the same time, the cost of maintaining the flux layer is also high.

(2) The advantages of the "dry" hot-dip galvanizing process are high output, low zinc slag generation rate, and cleaner air in the workshop. With the development of large-scale and high-efficiency modern hot-dip galvanizing enterprises, most hot-dip galvanizing enterprises adopt "dry method" hot-dip galvanizing.

2.1.2 Basic principle of batch hot-dip galvanizing

Hot-dip galvanizing, also known as hot-dip galvanizing, hot-dip galvanizing. Among the anti-corrosion methods of various steel materials, hot-dip galvanizing is the most widely used and the best performance.After the steel workpiece has undergone physical and chemical treatment, the workpiece is immersed in the molten zinc solution at a temperature of 430°C to 460°C (different workpieces are suitable for hot-dip galvanizing in different temperature ranges) or a higher temperature molten zinc solution. The iron base of the material reacts with the zinc liquid to form a Zn-Fe alloy phase layer + pure zinc layer, which covers the entire surface of the workpiece.The surface of the hot-dip galvanized galvanized layer has certain toughness, can withstand great friction and impact, and has good bonding strength with the iron matrix. This galvanizing method not only has the corrosion resistance characteristics of electro-galvanizing, but also has high hardness, high wear resistance and strong corrosion resistance that cannot be compared with electro-galvanizing due to the Zn-Fe alloy phase layer. Therefore, this hot-dip galvanizing is especially suitable for the protection of steel workpieces in strong corrosive environments such as various strong acids and alkali mist.The process principles of hot-dip galvanizing and electro-galvanizing are very different. Electrogalvanizing is the process of electrolysis to form a zinc coating on the cathode. In fact, electro-galvanizing is a deposition process in which zinc atoms are gradually precipitated. At the beginning of electroplating, fine small crystal nuclei are formed on the surface of the iron base. This single crystal nuclei increases with the extension of electroplating time, and finally connects together to form a galvanized layer.Contrary to this, hot-dip galvanizing is not a deposition process, but a process of melting zinc to iron, which is a galvanized layer formed by melting zinc to iron. This process is actually a process of "soldering zinc coating".The hot-dip galvanized layer is formed in three steps in high-temperature liquid zinc:

(1) The surface is melted by molten zinc.The surface of the iron matrix of the workpiece body material is melted by the zinc solution to form a Zn-Fe alloy phase layer.

(2) Zinc ions in the Zn-Fe alloy phase layer further diffuse into the iron matrix to form a Zn-Fe mutual-dissolution layer. Iron forms a Zn-Fe alloy phase layer during the process of being melted by zinc liquid, and continues to diffuse.

(3) The surface of the Zn-Fe alloy phase layer is covered with a pure zinc layer, and the pure zinc layer is cooled and crystallized to form a zinc coating. Therefore, the galvanized protective layer obtained by directly immersing the decontaminated and derusted steel materials in the zinc solution is very firm. At the same time, its "diffusion ability" and "coverage ability" are far better than electro-galvanized.The so-called "diffusion ability" and "coverage ability" refer to the uniformity and completeness of the distribution of the galvanized layer on the surface of the plated workpiece."Diffusion ability" is also called "spreading ability", which refers to the uniform distribution ability of the thickness of the galvanized layer."Covering ability" is also called "depth ability", "covering ability" or "landing ability".In terms of these two capabilities, hot-dip galvanizing is much stronger than electro-galvanizing. For example, the deep recesses on the surface of steel workpieces or the inner hole walls of tubular workpieces are often electro-galvanized very shallowly, or even not coated. And hot-dip galvanizing, no matter how complicated the shape of the workpiece, can obtain a good galvanized layer consistent inside and outside.Iron and steel materials are the main working materials of hot-dip galvanizing, and the melting point of zinc, the material of the galvanized layer, is much lower than that of steel. In addition to zinc (melting point of 419.5°C), commonly used coating metals include aluminum (melting point of 658.7°C), tin (melting point of 231.9°C) and lead (melting point of 327.4°C).

Our company mainly business scope is as follows:

1) The design, manufacture, installation, commissioning and training of the hot dip galvanizing lines, redesign and improve of the old galvanizing plants.

1. Jobbing galvanizing line for construction parts: such as steel tower , tube tower parts, high rails and lighting poles , etc.

2. Galvanizing lines for steel tubes:suitable for 1/2"-8" steel tube.

3. Galvanizing lines for small parts:suitable for bolts, nuts and other small parts.

2) The related chemical preprocessing of products and alloy

Our main products are : chemical pretreatment tanks, galvanizing furnace, zinc kettle, utilisation of fuel gas from the fuel furnace, drying pit.

If you have any questions, please contact our engineers for consultation, online.